Turnkey systems, premium quality, and lasting performance—powered by expert engineering.

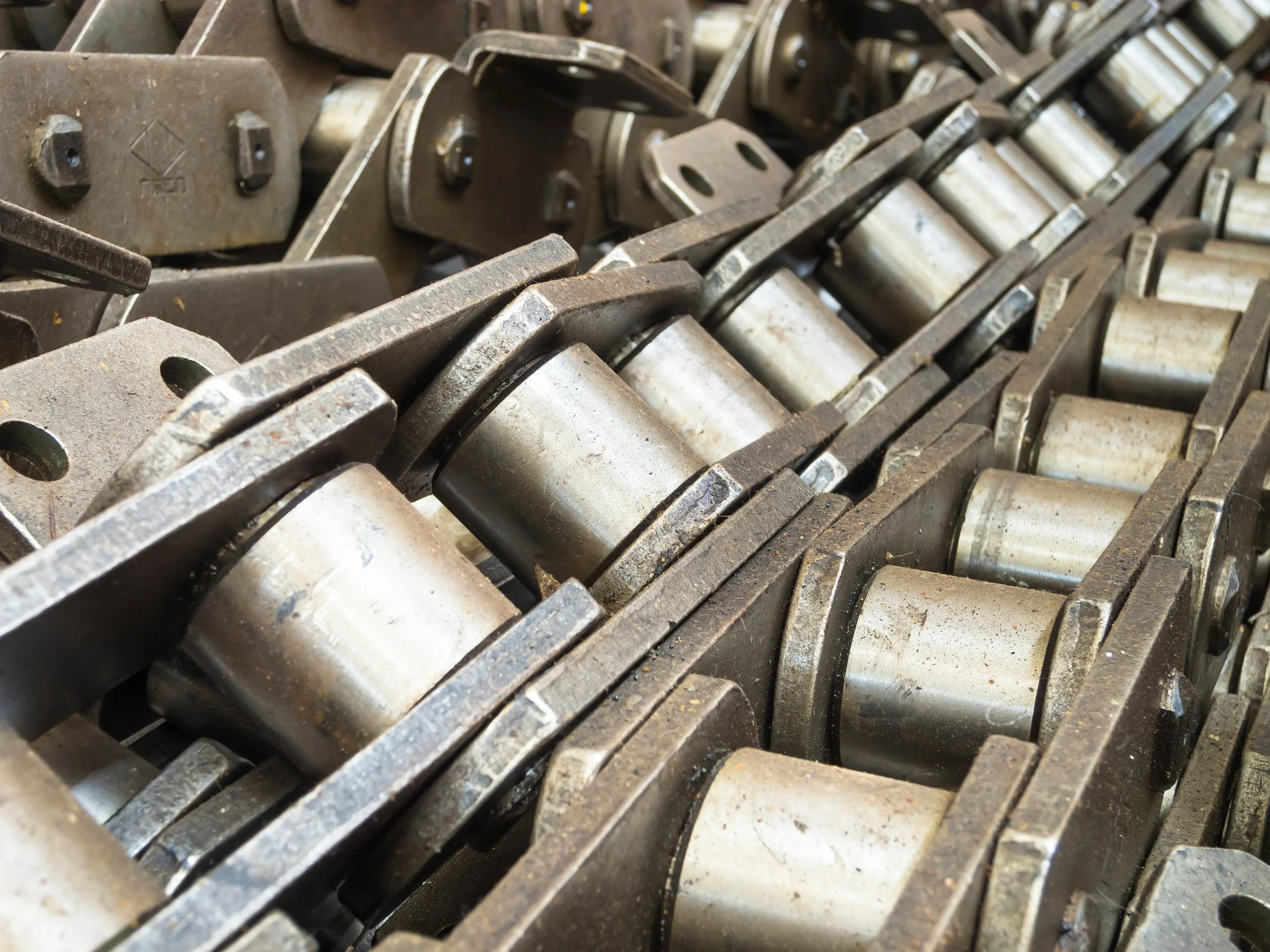

Since 1965, our partner Kelco has been manufacturing durable chains and sprockets for the asphalt industry. We provide A-L chain, which is heat-treated for maximum strength and wear life to withstand the hot, abrasive, and non-stop environment of asphalt plants.

Klockner Group has supervised Cascade Evaporator reworks for over 30 years, rebuilding more than 80 cascades. We precision-cut tube sheets for perfect alignment and leak-test each tube to ensure weld integrity. We manufacture high-quality tubes, tube sheets, shaft and hub assemblies, bushings, and custom hub bolts. Our field service technicians are available to diagnose problems and provide full inspections to keep your evaporator running at full capacity.

We deliver precision-engineered solutions to keep your operations running smoothly. With decades of expertise, our core services and high-quality products are designed to maximize efficiency, durability, and safety across industrial environments.

Our Products

Built to endure extreme loads and abrasive environments, our welded steel chains ensure long-lasting performance for drag, bucket, and apron conveyors.

Precision-machined sprockets and drive units guarantee smooth conveyor operation and extended chain life.

Complete head and tail shaft assemblies engineered for reliability and easy maintenance in heavy-duty conveyor applications.

From detailing and customized design to installation, we deliver engineering solutions tailored to your needs. Our belt, chain, bucket, and apron systems are built for reliability and performance.

Our certified welders craft durable platforms, mezzanines, supports, and stairs that meet the toughest industrial standards.

Leverage cutting-edge aerial and thermal drone technology for smarter maintenance and risk management.

Keep your facility at peak performance with our comprehensive maintenance and repair services.

From long-term maintenance partnerships to fast-turn emergency support, our teams keep critical systems running so you can focus on production.

"Klockner Group handled a complete mill shutdown for us. Their team was professional, efficient, and finished ahead of schedule. We'll be using them for all future projects."

- -Confidential, Operations Manager

"We needed a custom conveyor system for a new production line. Klockner not only designed a perfect solution but also installed it flawlessly, with minimal interruption to our existing operations."

- -Confidential, Plant Supervisor

Contact Klockner today for reliable, high-performance solutions that drive results.

Contact Our Team